Are you in the market for a mobile folding bar? A high-quality mobile folding bar offers an efficient combination of functionality and appearance. It can be easily moved and stored when not in use, yet lets you have a permanent looking bar when you need it. However, a poor quality bar can cause you more headaches and problems that you don’t already have. It’s essential to consider are the manufacturing quality and how mobile the bar actually is to make sure it meets your needs.

Are you in the market for a mobile folding bar? A high-quality mobile folding bar offers an efficient combination of functionality and appearance. It can be easily moved and stored when not in use, yet lets you have a permanent looking bar when you need it. However, a poor quality bar can cause you more headaches and problems that you don’t already have. It’s essential to consider are the manufacturing quality and how mobile the bar actually is to make sure it meets your needs.

Manufacturing Considerations

If you’re buying a mobile folding bar, you want something that’s going to last. The primary factor in this is the quality of the materials and construction. When you’re evaluating a mobile folding bar to see if it’s quality, here are the key qualities:

Metal Gauge

Gauge is a measurement of the the thickness of a given metal. The lower the gauge, the thicker the metal. Without getting too much into the manufacturing details, the key thing to know is that you want a gauge that’s thick enough to withstand being bumped or banged without denting, but not so thick as to add unnecessary weight and make the bar difficult to transport. In our tests, we determined that 18 gauge steel was the optimal combination of strength and weight for a mobile folding bar.

Powder Coat Finish

A powder coat finish preserves the look and integrity of the bar. The powder coat prevents the metal on the bar from rusting. This keeps your mobile folding bars in pristine condition even though it’s regularly exposed to spilled drinks and being wiped down.

Industrial Strength Locking Casters

The casters, or wheels, need to be sturdy. If you’re going to be wheeling this bar around, you don’t want the wheels to wear down and dent. This will make the bar harder to move around and a mobile folding bar that can’t be rolled around isn’t going to be very useful. Casters made from hardened rubber or a similarly resistant material are the best.

Impact Resistant Panels

Impact Resistant Panels

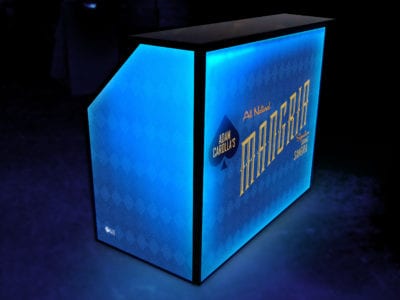

A final factor to evaluate is the strength of the panels. Like the metal, you want to select panels that are strong enough to resist the natural wear and tear of being moved around and banged into. If your considering using custom branding, having modular panels that can be changed in and out might be another important consideration for you. We use impact resitant acryllic panels because they they’re strong relative to their weight and can be removed and replaced as needed..

Understanding Mobility

Once you know that the mobile folding bar is well-built, you need to make sure that it’s going to be mobile in the way you want.

This question to ask yourself is are you planning on using it within one venue or mulitple venues?

If your going to move it around between venues, you should look at a modular folding bar. Modular bars can be taken apart piece by piece which makes them easier to transport when they can’t be rolled. That could include up and down stairs or on and off of a loading truck.

The downside to modularity is that it typically takes longer to set up since you have more pieces. A bar that isn’t modular will typically set-up and tear down much faster than a modular one, but you need to make sure you have a method of efficiently moving it between venues.

If you have a truck or trailer for transporting it or the venues are close enough where it can be rolled, this won’t be a problem.